Production of WAREX swap bodies

We have been manufacturing swap bodies in our own production plant in Javorník since 2018.

Swap bodies can be grouped with inter-modal transport units (UTI), which are suitable for European combined transport by road, rail, inland waterway and maritime transport.

Swap bodies are a very modern and efficient means of transport for combined transport, reducing the means of transport to a minimum and no crane is required for loading on the road.

The system of swap bodies allows you to minimise the downtime of vehicles and to combine multiple modes of transport, thus minimising the burden on the environment and reducing the traffic load on roads. The use of swap bodies eliminates the need to use handling equipment when loading on the customer’s road transport.

WAREX swap bodies comply with all required standards and regulations and are certified by the International Organization for Standardization.

WAREX spol s r.o., Czech Republic is the world´s first manufacturer producing galvanized swap bodies.

Galvanizing guarantees maximum corrosion protection, which extraordinarily exceeds the possible corrosion protection properties of cataphoretic coating treatment (KTL).

To achieve the highest degree of protection, the substructure, hot dip galvanized and swap body frame are, wall and roof sheets are plating galvanized.

Our technical know-how of the welding process along with the galvanization treatment allows us to produce the highest quality among the swap body constructions in the world.

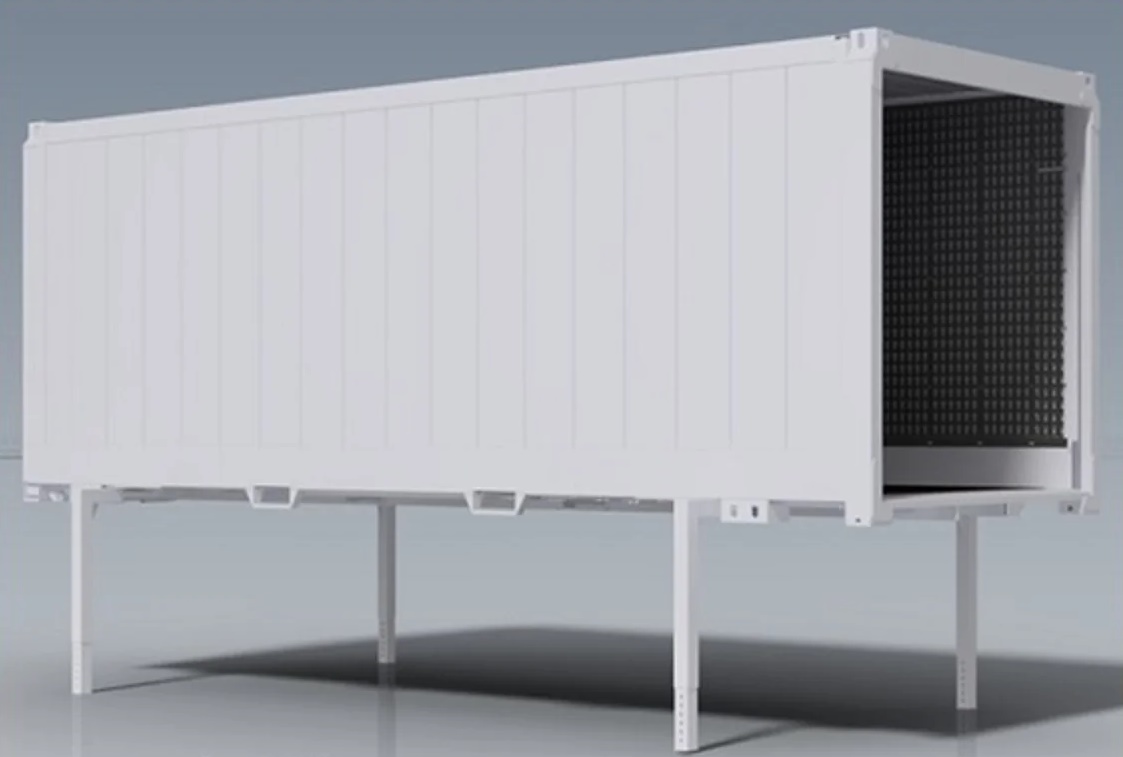

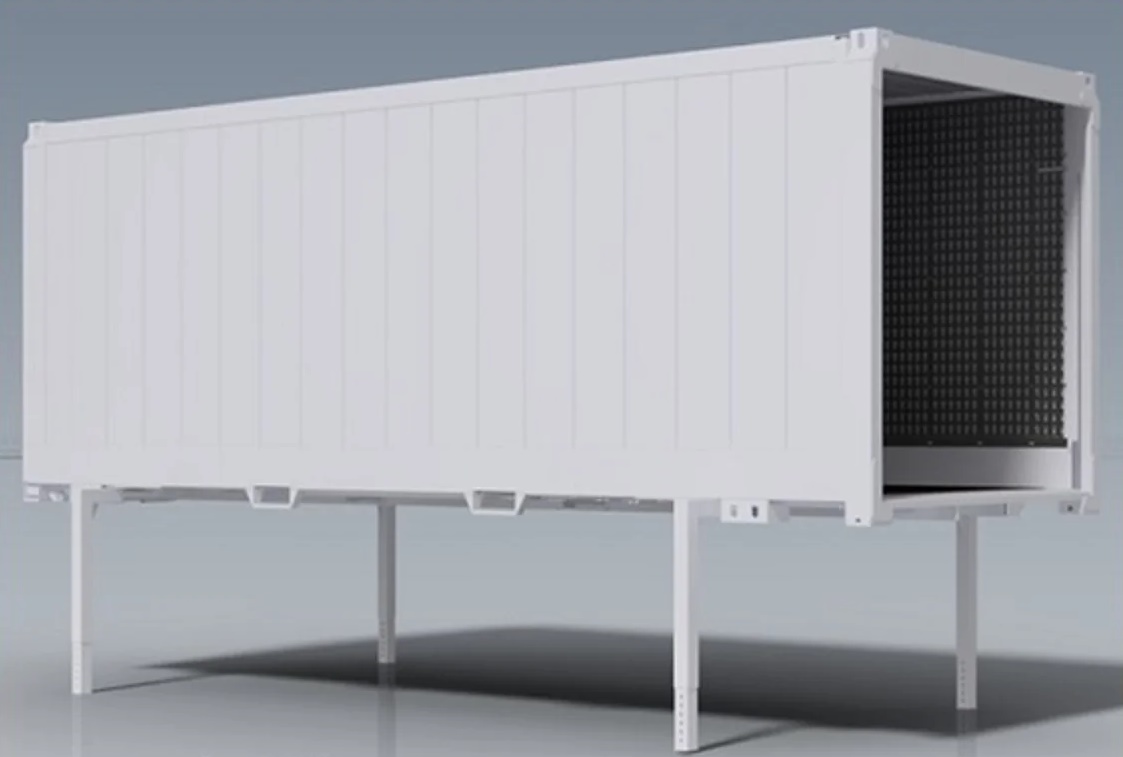

Swap bodie C745

Total length: 7,450 mm

Inner length: 7,295 mm

Inner width: 2,474 mm

Inner height: 2,555 (2,445) mm

Floor assembly height (incl. board): 151 mm

Clear portal height: 2,380 mm

Corner height: 2,750 mm

Loading height: 1,080–1,430 mm

Perm. total weight: 18,000 kg

Tare weight: 3,260 kg

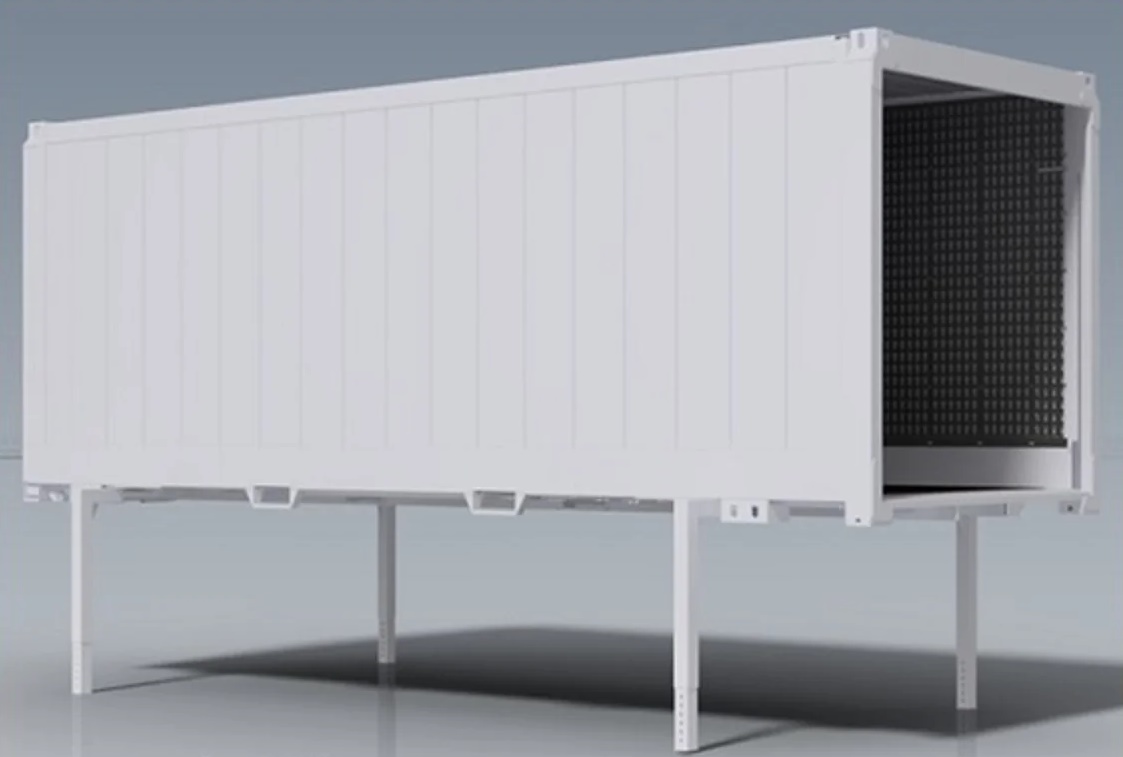

Swap bodie C745 smooth wall

Total length: 7,450 mm

Inner length: 7,295 mm

Inner width: 2,474 mm

Inner height: 2,555 (2,445) mm

Floor assembly height (incl. board): 151 mm

Clear portal height: 2,380 mm

Corner height: 2,750 mm

Loading height: 1,080–1,430 mm

Perm. total weight: 18,000 kg

Tare weight: 3,700 kg

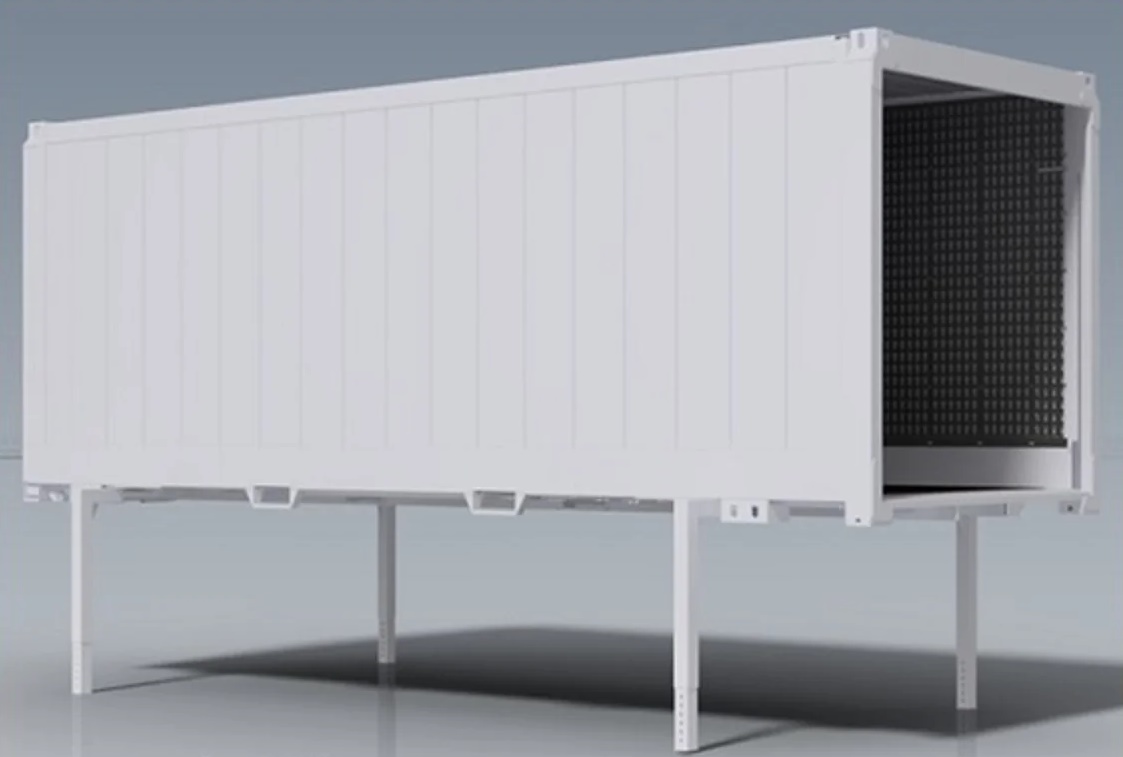

Swap bodie C745 smooth wall Jumbo

Total length: 7.450 mm

Inner length: 7.295 mm

Inner width: 2.474 mm

Inner height: 2.795 (2.685) mm

Floor assembly height (incl. board) 151 mm

Clear portal height: 2.620 mm

Corner height: 2.990 mm

Loading height: 1.080 – 1.430 mm

Perm. total weight: 18.000 kg

Tare weight: 4.500 kg

Swap bodie C745 Jumbo

Total length: 7,450 mm

Inner length: 7,295 mm

Inner width: 2,474 mm

Inner height: 2,795 (2,685) mm

Floor assembly height (incl. board): 151 mm

Clear portal height: 2,380 mm

Corner height: 2,990 mm

Loading height: 1,080–1,430 mm

Perm. total weight: 18,000 kg

Tare weight: 3,390 kg

Swap bodie C782

Total length: 7,820 mm

Inner length: 7,665 mm

Inner width: 2,474 mm

Inner height: 2 555 (2 445) mm

Floor assembly height (incl. board): 151 mm

Clear portal height: 2,380 mm

Corner height: 2,750 mm

Loading height: 1,080–1,430 mm

Perm. total weight: 18,000 kg

Tare weight: 3,400 kg

Swap bodie C782 Jumbo

Total length: 7,820 mm

Inner length: 7,665 mm

Inner width: 2,474 mm

Inner height: 2,795 (2,685) mm

Floor assembly height (incl. board): 151 mm

Clear portal height: 2,620 mm

Corner height: 2,990 mm

Loading height: 1,080–1,430 mm

Perm. total weight: 18,000 kg

Tare weight: 3,540 kg

Swap bodie C782 smooth wall

Total length: 7.820 mm

Inner length: 7.665 mm

Inner width: 2.474 mm

Inner height: 2.795 (2.685) mm

Floor assembly height (incl. board): 151 mm

Clear portal height: 2.380 mm

Corner height: 2.750 mm

Loading height: 1.080 – 1.430 mm

Perm. total weight: 18.000 kg

Tare weight: 4.550 kg

Swap bodie C782 smooth wall Jumbo

Total length: 7.820 mm

Inner length: 7.665 mm

Inner width: 2.474 mm

Inner height: 2.795 (2.685) mm

Floor assembly height (incl. board): 151 mm

Clear portal height: 2.620 mm

Corner height: 2.990 mm

Loading height: 1.080 – 1.430 mm

Perm. total weight: 18.000 kg

Tare weight: 4.700 kg

WAREX swap body components

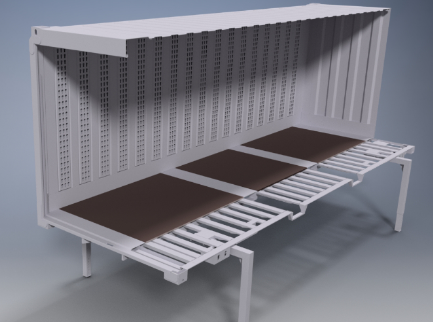

Floor

The floor consists of closed 3 mm-thick steel profiles, in the S235 JRH quality. Waterproof plywood of 21 mm thickness is used for the walkable layer. This combination ensures a high load capacity that allows the floor to be loaded up to 5,460 kg.

On the bottom part there is a 600 mm wide guiding tunnel made of closed profiles, which is used to direct the vehicle trailer during loading. Furthermore, there are openings for forklift handling and security elements for safe transportation. In the front there is a sliding ladder and a document box. There is a bumper in the rear to prevent mechanical damage while loading.

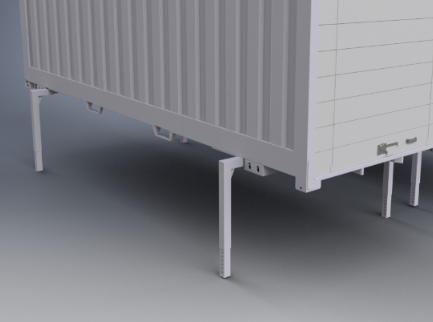

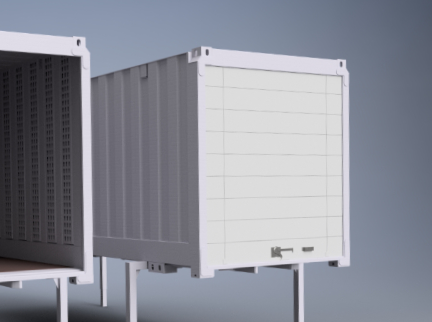

Supporting legs

These are a high-quality product from a renowned German company, which meets all safety standards, has high stability and easy handling when driving under them.

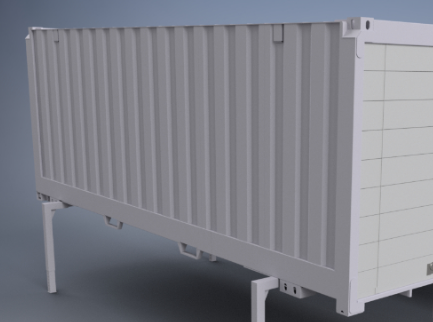

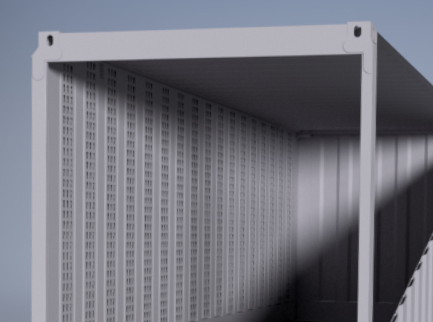

Side walls

The supporting frame is designed from bent profiles 3–4 mm thick. The external walls are made of profiled sheet metal with a thickness of 1.5–2 mm, which guarantees sufficient strength according to ČSN EN 283.

Air circulation is provided by four air vents located at the top of the longitudinal walls.

Securing cargo

On the inner walls there is a system of clamping holes, which guarantees enough possibilities and their combinations to secure any kind of load.

Sectional doors

The main entrance to the swap body is made of aluminium roller door that extend inwards under the roof structure. They enable the use of the entire clear passage of the swap body for loading.

Additional information

Surface treatment and labels

- The corrosion protection system is prepared based on ISO 12944-5

- The painting system for corrosive environment C4–M is according to standard 12944-2

- Two-component epoxy base, min. 80 µm

- Two-component polyurethane topcoat, RAL 9010, min. 100

- Advertising labels can be made according to the customer’s wishes

- Safety marking according to ČSN EN 283 and 284

The principle of loading and unloading on the vehicle and Other handling methods

Using the vehicle’s hydraulic system,the swap body is raised to extend the support legs. The driver then comes out with the trailer and the swap body remains standing on the support legs separately.

Handling can be done by means of side grippers, rope suspensions, but also by classic gantry cranes or other handling means as with conventional containers.

Sale or rental of swap bodies

In addition to the standard sale of swap bodies, we also offer the opportunity of long-term rental. Rental of swap bodies is a financially and capacitively interesting alternative to their purchase. Whether it is the sale or rental of swap bodies, you can solve everything with us under one roof. More information on rental of swap bodies can be found here.

Our production meets the following standards and regulations

CEN/TS 138553

swap bodies dimensions, design requirements, testing

ČSN EN 284

dimensions and general requirements

ČSN EN 283

swap bodies testing

CSC

safety approval

UIC

transport by railway

Ask us

Fast and unbound!

Are you interested in our production program, but not sure if this is right for you? There is nothing easier than to contact us. With one of our experienced dealers you will quickly find out everything you need!

Ask